Deep Tech Briefing #22:🛡️Unicorn in Defense Tech; 🔩Gates-backed Green Steel Pilot; 🏭 Plasma Precision Manufacturing; ⚛️ USA Startup's 6 GW Nuclear Plan; ♻️ AI Green Polyurethane

An insider’s update on Deep Tech Economy: Your dose of tech innovations, startups, exponential industries, policies, and market moves to stay ahead and capitalize on it.

Hey there! Welcome to this edition of Deep Tech Briefing, our Sunday column where we break down the week’s top developments in Deep Tech Startups and Venture Capital.

Subscribe for free to get it straight to your inbox every Sunday, and read it whenever you like!

In today’s edition

Andreessen Horowitz backs defense tech startup Saronic, now a unicorn

Transforming manufacturing through plasma-enhanced precision

Gates-backed start-up announces pilot green steel project with methane pyrolysis technology

USA startup exits stealth, announcing bold plan to develop 6 GW nuclear fleet

AI-powered green polyurethane: Balancing industry growth and environmental stewardship

✨ For more, see Membership | Partnership | Deep Tech Catalyst

🔸Andreessen Horowitz Backs Defense Tech Startup Saronic, Now a Unicorn

The defense industry is undergoing a major shift, with increasing attention and investment in startups developing groundbreaking and strategic technologies. Today, it’s worth highlighting that Saronic, just 18 months after its inception, has hit a $1 billion valuation after closing a $175 million Series B round led by Andreessen Horowitz. This round also saw participation from both new and existing investors, including 8VC, Caffeinated Capital, Elad Gil, and NightDragon, among others.

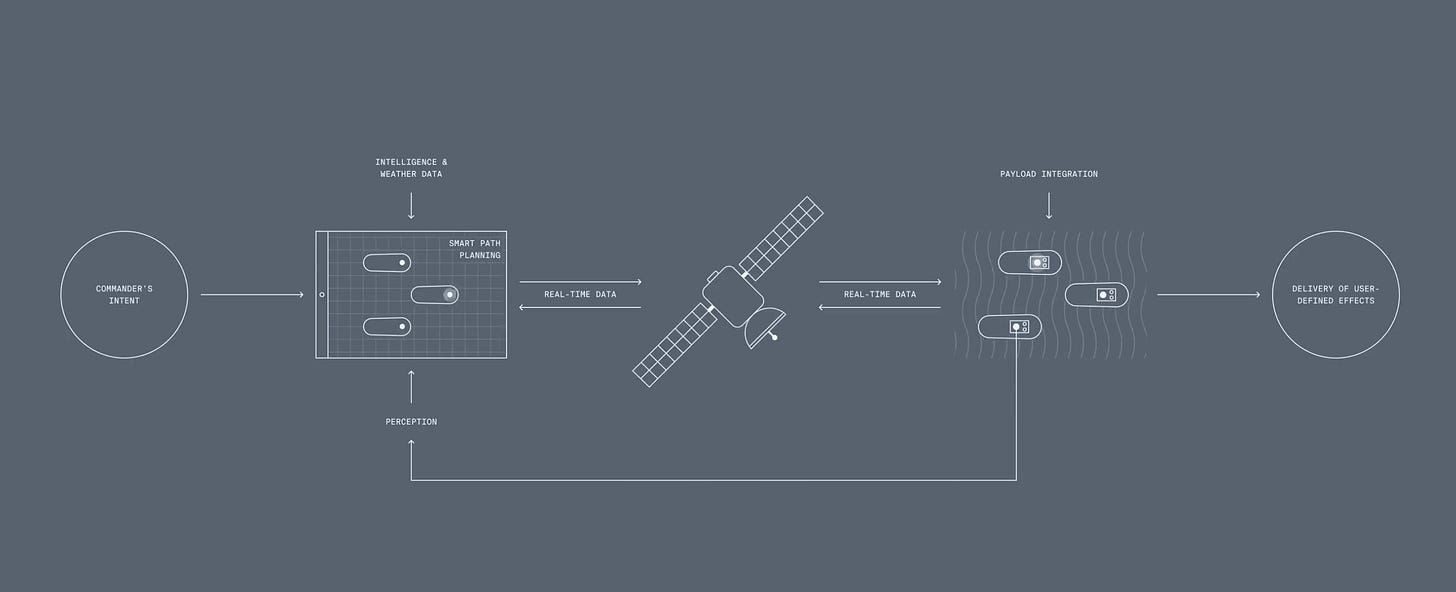

Founded by CEO Dino Mavrookas and Chief Commercial Officer Rob Lehman—veterans of SEAL Team 6 and the Marine Corps, respectively—is headquartered in Austin, Texas. The company designs and manufactures Autonomous Surface Vehicles (ASVs), essentially drones that operate on the water’s surface for the U.S. Navy. The startup has developed two prototypes so far: the six-foot Spyglass and the fourteen-foot Cutlass. Both vessels utilize sensors to autonomously conduct missions without human operator involvement.

Saronic’s competitive edge lies in its Modular Open Systems Architecture (MOSA), which ensures interoperability and cost efficiency. These vessels can carry different payloads tailored to specific mission requirements, making them versatile assets within the Navy’s hybrid fleet. By integrating seamlessly with manned systems, ASVs extend the reach and effectiveness of naval operations, enhancing mission success and minimizing risks to human operators.

“We are creating an entirely new capability for the maritime domain, one that delivers naval power without the costs and delays of a shipyard,” said Saronic CEO Dino Mavrookas.

The push towards integrating unmanned systems into naval operations has been driven by the increasing complexity and scope of maritime missions, necessitating innovative solutions that enhance operational capabilities while reducing personnel risks. This rapid scaling aligns with the Pentagon’s Replicator initiative, aiming to field thousands of unmanned systems within two years.

Saronic has stated that it will further expand its in-house production capabilities to ramp up the output of all its ASV models, and will also continue research and development of new autonomous capabilities for naval and maritime forces. This includes greater integration of technology and payloads with government and commercial partners.

On an international level, Saronic plans to use its latest investment to expand its services to partners in key markets. With the backing of top-tier investors and a clear vision for the future, this unicorn is set to make significant waves in the defense tech space, delivering cutting-edge solutions to enhance maritime security and operational efficiency.

🔸 Transforming Manufacturing Through Plasma-Enhanced Precision: A Paradigm Shift in Material Science

In the realm of advanced manufacturing, the demand for precision, efficiency, and quality has never been higher. Yet, many industries grapple with significant blind spots in their production processes, leading to considerable waste and inefficiencies. These inefficiencies stem from a limited understanding and control over the properties of the materials used, resulting in wasted production time and increased costs. This issue is particularly pronounced in sectors like battery manufacturing, where up to 40% of initial production may be discarded due to quality issues. Such variability not only drives up costs but also hinders the return on investment for manufacturing facilities.

SirenOpt, leveraging proprietary cold atmospheric plasma (CAP) technology and physics-based machine learning developed by co-founders from the Department of Chemical Engineering at the University of California, Berkeley, addresses these challenges head-on. Their innovative platform provides